It is rewarding when a company does well but growth brings its own challenges too. “Our logistics infrastructure was already at bursting point. Our old, predominantly manual warehouse with capacity for only 1500 pallets could no longer cope with the annual sales increases of more than 20 percent in some cases”, explains Andreas Prey. The 33-year-old is Logistics Manager at PSZ electronic GmbH in Vohenstrauss in the district of Neustadt an der Waldnaab in the Upper Palatinate. The company produces and assembles cable and system solutions for heating and ventilation technology, mechanical engineering, plant engineering, tool- building and special vehicle construction, as well as products for market leaders in medical technology. PSZ electronic employs around 1000 people world-wide, with production facilities spread across Germany, the Czech Republic, Albania and Tunisia.

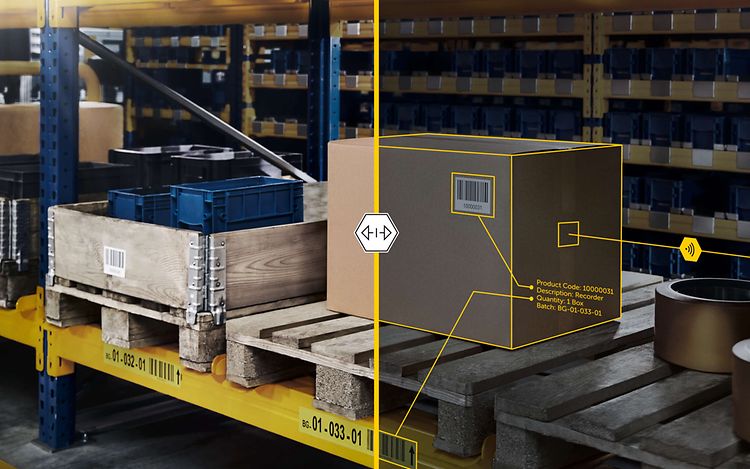

The logistics centre in Vohenstrauss is where everything comes together: It is the central hub designed to oversee the movement of all raw and finished goods. The logistics centre not only controls the flow of materials between the various production sites, but also the delivery to the target customers. That is a fairly demanding task. “We currently have several tens of thousands of items in our product range, which have to be packed in a wide variety of variants and labelled according to customer specifications”, says Prey. To achieve this, the company uses QR codes. These two-dimensional codes with their matrix of black and white squares have great advantages in terms of information density over simpler barcodes, such as the EAN or NVE codes commonly used in logistics.

The customer becomes a partner

In his search for a new, more efficient logistics solution, Prey sought expert advice: “As Jungheinrich is one of our customers, we quickly got in touch with our colleagues to discuss which method of storage expansion and system conversion would best suit our requirements”, recalls Prey

“The question we asked was: How can the existing space be better utilised to achieve maximum storage capacity? And not forgetting: How can we ensure that we can react flexibly to the challenges of the future?” reveals Prey.

The result of the subsequent intensive consultation and project planning process with Jungheinrich logistics experts from Bavaria was a complete reconstruction of the warehouse. The conventional wide-aisle warehouse was to be replaced with a semi-automatic narrow-aisle warehouse with capacity for more than 5000 pallets. To improve order picking efficiency, safety and ergonomics, the system was designed for crosswise stacking with a racking depth of 800 millimetres. The racks are approached by two EKX 410 high rack stackers. The stackers are equipped with wire guidance, terminals, scanners and warehouse navigation and can be operated intuitively and extremely reliably by PSZ warehouse staff. For example, the press of a button is all it takes for the warehouse navigation system to lead the narrow aisle truck to the destination. In the Warehouse Management System, the Jungheinrich WMS Series 2, all the information is gathered together. Even this basic variant of the WMS is able to synchronise the entire material and information flow. This allows the warehouse to be optimally managed and controlled. Last but not least, the software can be flexibly adapted to changes in the warehouse thanks to a large number of different modules and is therefore future-proof.

Optimum support of the storage and retrieval processes

“This system”, says Prey, “takes our logistics infrastructure to a whole new level. With the new warehouse, we can now optimally map and support the storage and retrieval processes for all our various items. This could involve the movement of standard Euro pallets, mesh boxes or cartons and containers for order picking in small parts logistics”, explains Prey in reference to the enormous variety of products and the resulting diverse requirements in terms of packaging and packaging dimensions. For example, a wire harness from PSZ could be eight metres or just a few centimetres long.

The move from the old warehouse to the new warehouse took place over the New Year period 2016/2017. “We deliberately wanted to make a clean break and complete the move from the old to the new warehouse in a single day”, says the PSZ logistics manager. “It was fantastic teamwork”. Over four weeks in December, everyone involved — the employees of PSZ and their colleagues from Jungheinrich — pulled together. For Prey, it was crucial to involve the employees who would eventually have to operate the system independently in the project from the outset. “The system is easy to under- stand and you can quickly familiarise yourself with the various functions”, says Prey.

“Our employees liked our new narrow aisle warehouse and the WMS Series 2 right away. From the point of view of the employees, the new semi-automatic warehouse not only simplifies their work processes, it makes the processes much more transparent, so they can better understand their role in the organisation as a whole. This in turn helps them to identify with their work”.

Enhanced overview and an end-to-end ordering process

The logistics specialist is particularly pleased that the quality of the work of each individual employee has improved significantly with the construction of the new warehouse. Prey explains how things have improved: “Whereas the employees in the old warehouse spent a huge amount of time searching for a specific product, they now know — thanks to the real-time stock management function — what quantity of the desired item can be found in which location at any given time. The radio data solution combined with the warehouse management system, Jungheinrich WMS Series 2, creates the perfect environment. For the first time ever, order processing is paperless. The result is an enhanced overview, increased transparency and an end-to- end ordering process. The work is much more efficient and simpler, and the error rate drops to a minimum”.

Andreas Prey

Logistics Manager at PSZ electronic GmbH in Vohenstrauss in the district of Neustadt

“The semi-automatic warehouse and the WMS make us even more in tune with our production plants all over the world, but also more in tune with our customers."

Increasingly ambitious automatic systems

“The semi-automatic warehouse and the WMS make us even more in tune with our production plants all over the world, but also more in tune with our customers and their needs”, emphasises Prey. “Thanks to digitisation and our comprehensive, intelligent intralogistics concept, we are now capable of much more sophisticated logistics processes than ever before”. That is a great success. “Everyone who visits us here in Vohenstrauss wants to see the new facility. We like to show them around — the warehouse looks fantastic and really impresses visitors”.

Logistics Manager, Andreas Prey, is enthusiastic about the cooperation with the team of experts from Jungheinrich: “Everything was perfect from the outset: from the planning phase and the implementation phase to the ‘go live’ date and the run-up phase overseen by the Jungheinrich experts”. Such intense cooperation is rare in this industry and should not be taken for granted. The personal highlight for Prey was the day of the changeover on 2 January 2017: “Everything worked out the way we envisaged — a seamless move taking intralogistics to a whole new level. Now we are prepared for the future. Things could not be better. Whatever the future brings in terms of further growth and new customer requirements, we are ready for it”.