Automation & Systems

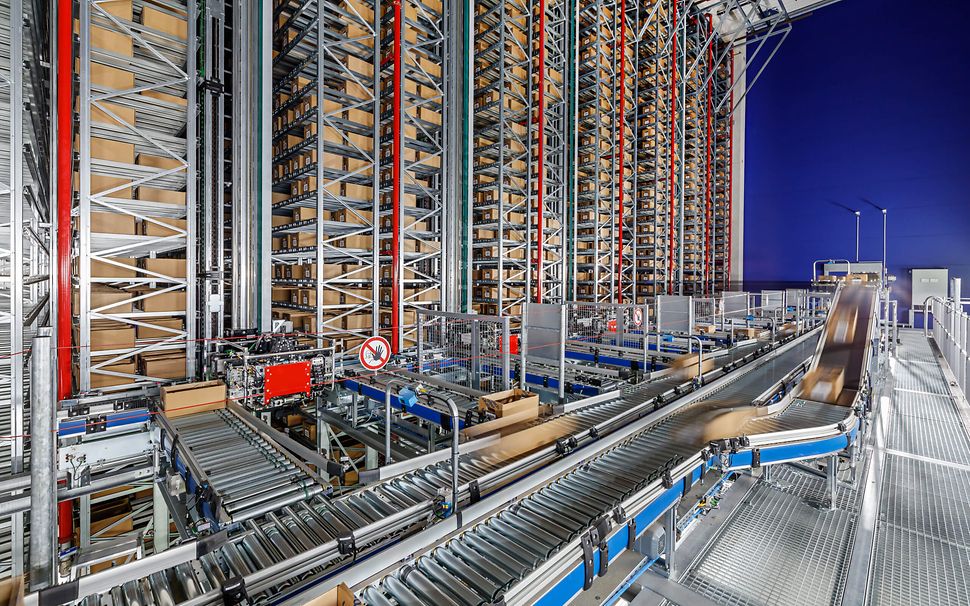

Are you looking for future-proof intralogistics that flexibly adapt to your current needs and offer room for growth? Then why not take advantage of our versatile automation solutions – from mobile robots and stacker cranes to software solutions – to sustainably optimise your work processes and material flows.

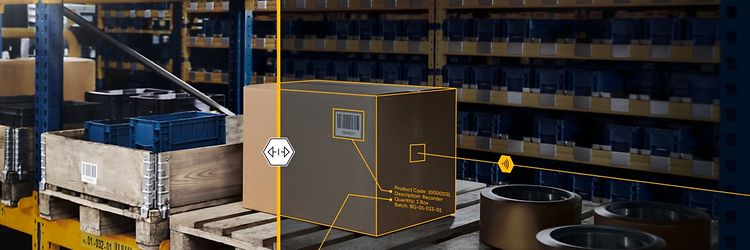

Whether as a stand-alone solution or perfectly integrated into your system landscape – as a specialist partner for holistic automation and digitalisation, we can implement a customised overall system for you that automatically increases the efficiency of your warehouse.

Intelligent use of automation potential

Are you wondering what level of automation is right for your warehouse? Based on our many years of experience and expertise, we answer this question on a customer-specific basis and develop customised solutions for the partial or full automation of your warehouse. As a general contractor, we will assist you in everything from planning and implementation to service and support, thus ensuring the success of your automation strategy.